Aluminum Foundry is perfect for engineers in aluminum casting

Wiki Article

The Duty of Aluminum Foundry in Enhancing Production Performance Throughout Diverse Sectors

Aluminum factories serve a crucial function in contemporary production by enhancing manufacturing efficiency throughout numerous industries. They harness progressed techniques and lasting techniques to enhance operations and minimize waste. The influence of Aluminum reaches markets such as auto, aerospace, and building, where its one-of-a-kind properties enhance performance. Nonetheless, the challenges faced by these factories can shape their future. Comprehending these characteristics reveals a complex landscape of advancement and adjustmentThe Importance of Aluminum in Modern Production

The adaptability of Aluminum enables a large array of fabrication methods, consisting of casting, extrusion, and machining. In addition, its recyclability further underscores its value, as recycled Aluminum calls for considerably less energy to create than brand-new Aluminum, lining up with modern ecological objectives. As sectors proceed to develop, Aluminum's special qualities and flexibility assure it remains a crucial product for driving advancement and performance in producing procedures. Its payments extend past capability, sustaining financial growth and sustainability campaigns across the world.

Trick Procedures in Aluminum Foundries

In Aluminum factories, numerous essential processes are vital for attaining high production efficiency. Thawing and alloying techniques, in addition to molding and spreading approaches, play a critical role in shaping the final product. Furthermore, carrying out strict top quality control measures warranties that the result fulfills industry requirements.Thawing and Alloying Techniques

Melting and alloying are fundamental processes in Aluminum shops, their performance considerably impacts total manufacturing quality and price. The melting process normally includes making use of electric furnaces or gas-fired systems, which permit for precise temperature control. This assures that Aluminum reaches its suitable melting point, decreasing energy consumption. Alloying, on the various other hand, entails the addition of specific elements to accomplish preferred product properties, such as toughness and deterioration resistance. Techniques such as pre-alloying and in-situ alloying are generally utilized to improve consistency and decrease waste. Mindful tracking throughout both melting and alloying phases is important, as it directly influences the material attributes and warranties compliance with sector standards, inevitably leading to boosted manufacturing efficiency across numerous sectors.Molding and Casting Methods

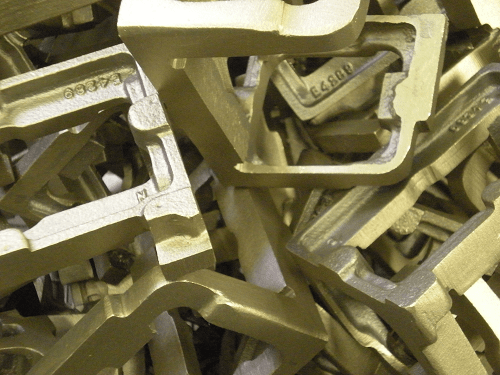

A selection of molding and spreading techniques are vital to the performance and top quality of Aluminum shops. Amongst these approaches, sand spreading, pass away spreading, and irreversible mold and mildew casting stick out due to their special benefits. Sand spreading provides versatility for complex shapes and is affordable for reduced production volumes. Die spreading, understood for its precision and repeatability, is ideal for high-volume production, giving exceptional surface area coatings and dimensional accuracy. Irreversible mold and mildew casting combines the benefits of both sand and pass away casting, allowing for far better mechanical homes and lowered product waste. Each approach serves details applications across varied industries, enabling Aluminum shops to maximize production processes, minimize lead times, and satisfy differing consumer needs effectively.High Quality Control Steps

Assuring high-grade Aluminum items needs extensive quality assurance actions at every phase of the Foundry process. These steps begin with the option of basic materials, where detailed testing for impurities and structure is vital. Once materials are accepted, assessments throughout the molding and casting phases check dimensions and surface quality to stop problems. Advanced methods, such as non-destructive testing, are utilized to identify inner imperfections that might endanger item honesty. Additionally, process control systems continuously monitor temperature and alloy composition to maintain consistency. Last inspections, including mechanical residential property screening, verify that the products meet industry standards. By implementing these stringent quality assurance protocols, Aluminum shops boost manufacturing effectiveness and guarantee the reliability of their items throughout diverse industries.Developments Driving Production Performance

Technologies in Aluminum shops are reinventing production efficiency via innovative casting techniques and the assimilation of automation and robotics. These advancements not only simplify procedures but additionally improve precision and lower waste. Furthermore, sustainable product developments are contributing to even more eco-friendly methods within the sector.Advanced Casting Techniques

Many sophisticated casting strategies are transforming the Aluminum Foundry sector, significantly boosting production performance. Techniques such as die spreading, sand casting, and financial investment casting have actually evolved, enabling raised accuracy and lowered waste. Advancements like computer-aided layout (CAD) and simulation software application enable factories to maximize mold style and predict prospective concerns before production, decreasing costly errors - Aluminum Foundry. In addition, making use of alloy advancement strategies boosts material properties, causing items that fulfill stringent performance demands. Strategies such as quick prototyping and 3D printing are also getting grip, facilitating faster turnaround times for complicated geometries. These improvements not just simplify production processes but also add to sustainability efforts by minimizing power usage and boosting product application in the Aluminum spreading sector

Automation and Robotics Integration

The assimilation of automation and robotics in the Aluminum Foundry field is reinventing manufacturing efficiency. By utilizing innovative robot systems for tasks such as molding, pouring, and completing, shops are considerably minimizing labor Aluminum Foundry prices and minimizing human error. Automated processes improve manufacturing lines, enabling faster turn-around times and consistent quality in produced elements. Furthermore, the execution of real-time monitoring systems makes it possible for drivers to track efficiency metrics and optimize process proactively. Robotics also improves safety and security by taking control of unsafe jobs, thereby reducing workplace accidents. As the technology remains to evolve, the Aluminum Foundry industry is poised to utilize these innovations further, ensuring competition and responsiveness in a significantly demanding market.

Lasting Product Innovations

As the Aluminum Foundry market seeks to enhance manufacturing performance, lasting material developments are emerging as an essential factor. These innovations consist of the advancement of environmentally friendly alloys and making use of recycled Aluminum, substantially lowering the environmental impact of manufacturing processes. Advanced techniques, such as additive production and green spreading techniques, enable shops to reduce waste while improving product residential properties. Additionally, the assimilation of bio-based binders and finishes results in much healthier working settings and lowers exhausts. The adoption of life process evaluation tools more aids factories in determining sustainability chances, straightening with worldwide trends toward accountable manufacturing. These improvements not just improve manufacturing efficiency however additionally position the Aluminum Foundry industry as a leader in lasting commercial practices.Environmental Sustainability in Aluminum Spreading

While Aluminum spreading has actually long been a staple in manufacturing, its environmental effect has actually motivated a change towards more sustainable methods. Lots of shops are currently adopting environment-friendly strategies to minimize waste and energy consumption. By using recycled Aluminum, shops considerably reduce the need for virgin materials, thus saving all-natural sources and reducing greenhouse gas discharges.Advancements such as sophisticated melting modern technologies and boosted heater layouts furthermore improve energy effectiveness. Carrying out closed-loop systems enables for the recycling of scraps and by-products, minimizing landfill payments. On top of that, making use of water-based finishings and biodegradable products in the spreading process reduces harmful exhausts and environmental toxins.

As sectors progressively focus on sustainability, the Aluminum spreading field is aligning with these worths, showing that economic development and environmental duty can exist together. This commitment to lasting practices not just benefits the setting however additionally settings Aluminum foundries as leaders in accountable manufacturing.

Applications of Aluminum Parts in Various Industries

Aluminum elements are increasingly used throughout different sectors due to their one-of-a-kind properties, which consist of light-weight stamina, deterioration resistance, and excellent thermal conductivity. In the vehicle sector, Aluminum is necessary for producing lighter cars, adding to improved fuel effectiveness and lowered emissions. The aerospace market leverages Aluminum alloys for airplane components, taking advantage of their high strength-to-weight ratio, which boosts efficiency and safety.In building, Aluminum is preferred for home windows, doors, and roofing because of its longevity and aesthetic charm. The electrical market uses Aluminum in power lines and components, making the most of its conductivity and resistance to rust. In addition, the durable goods sector utilizes Aluminum in product packaging and house items, advertising sustainability via recyclability (Aluminum Foundry). Overall, Aluminum components play an important duty beforehand technical technologies and functional performances throughout varied markets, highlighting their relevance in modern manufacturing and layout

Challenges Faced by Aluminum Foundries

Numerous challenges challenge Aluminum shops, influencing their performance and efficiency. One considerable issue is the volatility of resources rates, which can rise and fall unexpectedly, impacting operational costs and earnings margins. Furthermore, factories typically grapple with stringent ecological guidelines, needing expensive investments in lasting methods and waste management systems. Labor scarcities present another difficulty, as the knowledgeable workforce needed for specialized procedures ends up being increasingly limited, causing potential hold-ups and quality assurance issues.In addition, technological assimilation presents challenges; factories must continually adapt to advancements in automation and electronic tools to continue to be affordable. Ineffectiveness in production procedures, such as inadequate melting and casting strategies, can also impede outcome. Finally, the demand for tailored solutions across different fields pressures factories to balance adaptability with performance, complicating production routines. With each other, these challenges create a complex landscape that Aluminum factories need to browse to improve their total performance.

Future Fads in Aluminum Foundry Modern Technology

As the Aluminum Foundry sector advances, arising technologies are set to transform production processes and enhance efficiency. Developments in automation, such as robotics and expert system, are expected to improve operations, reduce labor prices, and boost accuracy. On top of that, improvements in 3D printing innovation will permit the quick prototyping of intricate Aluminum elements, minimizing lead times and material waste.In addition, the integration of IoT (Internet of Points) will certainly enable real-time monitoring of manufacturing processes, enabling anticipating maintenance and minimizing downtime. Sustainability will certainly likewise play a critical role, with a boosting focus on recycling and power effectiveness in Foundry operations.

Regularly Asked Inquiries

What Are the Prices Linked With Aluminum Foundry Manufacturing?

The expenses related to Aluminum Foundry production include basic material expenses, labor prices, energy consumption, upkeep of tools, and expenses. These aspects collectively influence the total economic stability and performance of the Foundry operations.How Do Foundries Ensure Quality Control in Aluminum Spreading?

Factories ensure quality control in Aluminum spreading with rigorous screening methods, including material evaluation, dimensional examinations, and procedure tracking. Implementing standard procedures and utilizing advanced modern technologies assists maintain uniformity and meet industry requirements throughout manufacturing.What Precaution Are Applied in Aluminum Foundries?

Safety and security procedures in Aluminum foundries consist of personal protective tools, appropriate ventilation systems, routine safety and security training, emergency methods, and devices upkeep. These methods intend to reduce threats, guaranteeing the health of workers and preserving functional efficiency.For how long Does the Aluminum Casting Refine Usually Take?

The Aluminum spreading process normally takes several hours to a number of days, relying on factors like the complexity of the layout, the size of the cast, and the certain strategies employed by the Foundry.What Skills Are Required to Function in an Aluminum Foundry?

To operate in an Aluminum Foundry, individuals need skills such as metallurgy expertise, machining effectiveness, attention to detail, analytical capabilities, and synergy. Safety and security awareness and technical experience in casting processes are also vital for efficient procedure.Its recyclability better underscores its significance, as recycled Aluminum requires significantly less energy to create than new Aluminum, lining up with contemporary environmental goals. A variety of molding and casting methods are crucial to the effectiveness and high quality of Aluminum factories. Developments in Aluminum factories are reinventing production efficiency through advanced spreading strategies and the combination of automation and robotics. Numerous advanced spreading strategies are transforming the Aluminum Foundry industry, considerably boosting manufacturing effectiveness. Foundries assure top quality control in Aluminum casting through strenuous screening protocols, consisting of product analysis, dimensional inspections, and procedure tracking.

Report this wiki page